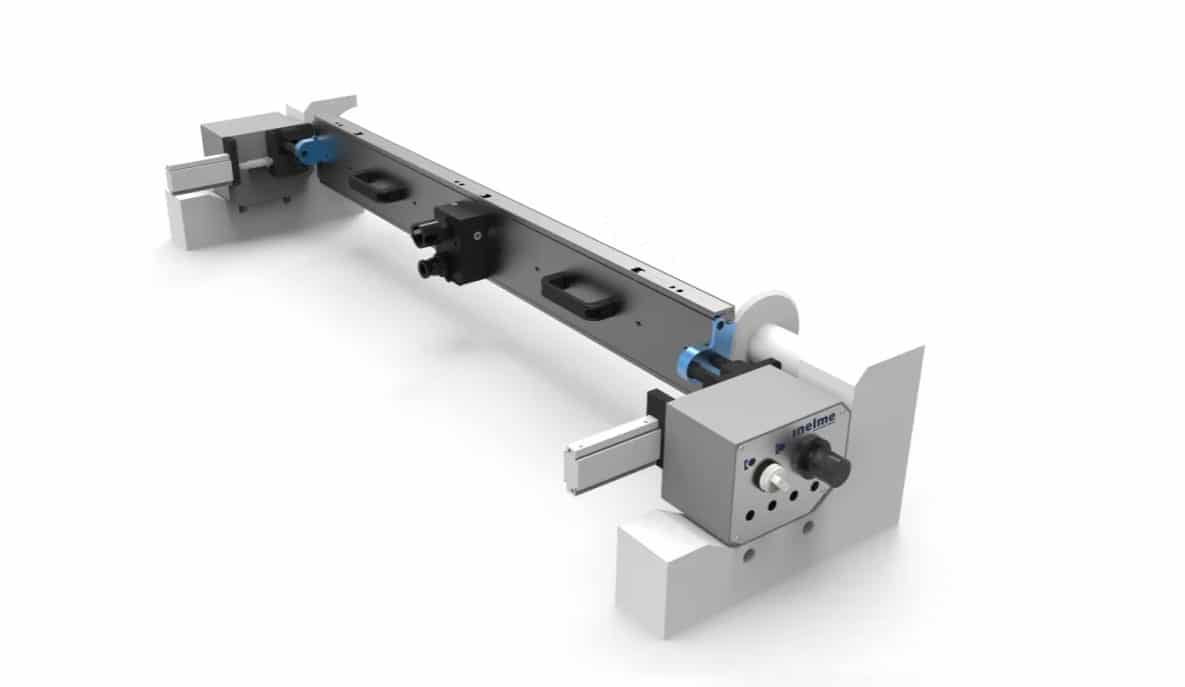

On this occasion, Inelme would like to present you with some of the most important pieces in the graphic industry sector and, more specifically, in that of flexography: the Doctor Blade Chamber.

The doctor blade chamber was born from the evolution of the flexo inking system made up of rubber and anilox rollers, working in contact to dose the ink that the latter delivers. The replacement of the pressure roller (rubber) by a system, first single knife and later double knife in closed chamber, was a great advance for the quality of flexographic prints.

What is and why is it important in flexography

Manufactured in different materials, aluminum, stainless steel or carbon fiber, its main objective is to regulate the amount of ink that the anilox delivers, achieving uniform colors at any printing speed, as well as offering the possibility of very low contributions, compared to the previous system. , indispensable in color selection prints.

The doctor blade chamber is mainly made up of three essential elements: the body, made of different materials, the blades, one for entry and one for exit, made of steel or plastic, and the side shutters, which keep the ink inside the camera and they are mainly made of foam or rubber depending on the needs (printing speed or duration of the job to be printed. Foam ones are especially indicated for short runs, while rubber ones for long runs.

Benefits of having a doctor blade chamber

The most important advantage of using a doctor blade in flexographic printing bodies is the uniform filling of the ceramic anilox roll pockets, as it makes prints exceptional and eliminates the problem of color enhancement by increasing print speed from older rubber pressure roller printing systems that let more ink pass with increasing speed.

What to take into account when choosing a Doctor Blade Chamber?

• Ease when changing the blades. Since it is necessary to renew them from time to time, whether they are made of steel or plastic, this is a very important factor. It is essential that it is not necessary to use tools if not levers that, with a simple movement of the hand, allow the blades to be released, changed and locked.

• Resistance and lightness. Indispensable that a doctor blade chamber is very resistant to bending to avoid defects in the ink supply in the central area of the anilox. Light to facilitate handling, normally made of aluminum, it is important to pay attention to the anodized applied to avoid corrosion.

• Hermetic seal. These chambers have a hermetic closing system on the sides called shutters, which prevents ink leaks and are preferably made of elastomer that is resistant to the chemicals used in the ink.

• Ease of assembly and disassembly. The doctor blade chamber must be able to be assembled and disassembled from the printing body quickly (in the same way as with the blades it is important that it is not necessary to use tools) and it is advisable that with a simple turn of 90 ° it can remain in an upright position to allow the change of blades mounted on the printing body.

Are you interested in learning more about the doctor blade camera? Contact Inelme and its professionals will answer all your questions. You will find them on the phone number +34 961 47 10 85 and on the email inelme@inelme.com.