INK DISPENSING

Solutions for the professional of flexography and rotogravure

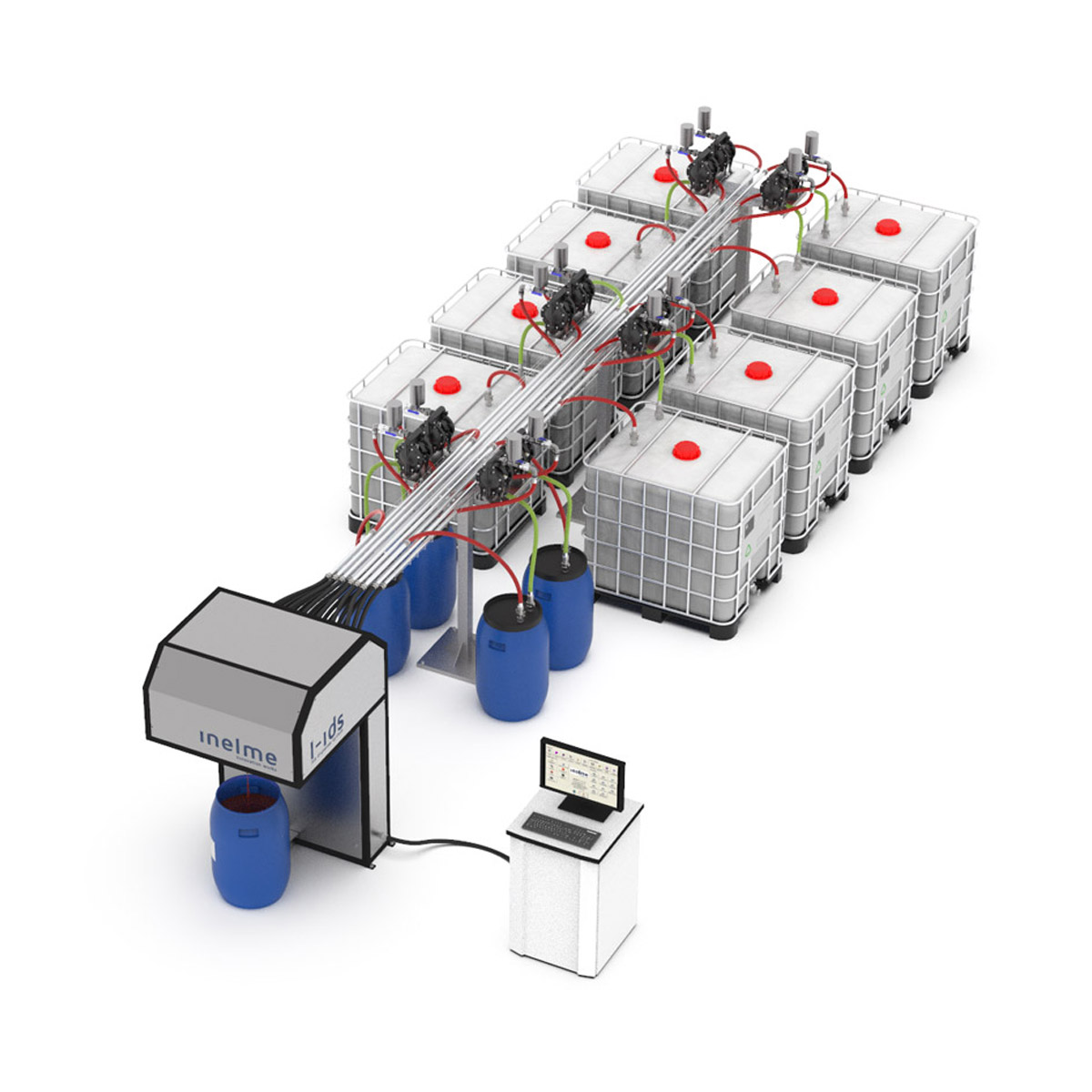

I-IDS ink dispenser

The I-IDS ink dispenser with platform for 300 kg is designed to obtain any mixture of colors , up to a total of 32 colors, with an accuracy of 1 gram.

The system has been approved according to the ATEX standards, to work in potentially explosive environments, through the Exp and Exia protection, in the case of the use of solvent-based inks.

To prepare the mixture, the dispensing unit is equipped with nozzles with pneumatic action valves with double dosing flow. This is done directly in the cube located on top of a precision scale that ensures the proportions.

The entrance and exit of the cube to the dosing area is done by means of a pneumatic cylinder, avoiding manipulation by the operator.

Each ink line is equipped with a pneumatic pump, which takes the ink from the tanks to the dosing area. The assembly of the ink tanks is adapted to the needs of the user and can be organized in different configurations. Each of the lines is controlled by software, to perform periodic recirculations of ink, in order to prevent the ink from drying in the tube and to avoid problems of obstruction.

INELME INKS DISTRIBUTOR

ALL THE CONTROL FROM THE INTERACTIVE SOFTWARE

The entire ink dispensing system is guided by an interactive software, equipped with a touch screen.

The software, in addition to controllingthe dosage of the ink, creating recipes for mixtures, verifying the proportions, is able to control the inventory of the bases used in the system and store them in the warehouse.

It includes a personal computer and a full size monitor in a pressurized enclosure with air purge, with protected keyboard and mouse. In addition to an inkjet printer to print reports and labels for formulations.

Once the formula for the final ink is entered, the computer program can perform the following functions:

It should be noted that there is no limit for data entry, you can enter as many formulas as necessary, even remotely through MODEM.

By presenting the price of each base ink, you can obtain the following data:

- Price of each ink formulation per kilogram

- Total consumption price of each base

- Total price of all bases

- Consumption of each base in kilograms

- Total consumption of all bases in kilograms

- Total price of all formulations

- List of all the bases that go into each formulation

- List of all formulas that enter a base

RECOVERY OF INKS

It is important to consider the possibility of recovering and managing excess ink quantities after each print job when preparing a new ink. When ink remains after a job, it will be taken to the I-IDS to weigh the remaining ink and store the data in its database, along with the formula for that color. In this way, when there is a new requirement to prepare a specific dose of a specific formula, the software will warn the user of the existence of an amount X of that ink, already available in the inventory of the storage warehouse. In addition, the remaining ink can can be placed in the I-IDS and can be filled with the same type of ink until the desired amount is reached. This allows the possibility of obtaining ink immediately, reducing delivery times as well as limiting the ink remaining for each job.

As an option, it will be possible to measure the concentration of solids / solvent for the inks that the user wants to store in the warehouse and these values will be maintained whenever it is necessary to prepare another batch of that mixture.

DO YOU WANT MORE INFORMATION ABOUT THE INK DISPENSING?