INK CONTROL SYSTEM

Solutions for the Flexography and Gravure Professional

Our ink control system I-ICS controls the most important parameters of the flexography and gravure inks. By means of sensors, pigment concentration, viscosity, pH and temperature are measured that are automatically regulated, in this way a color reproduction with minimum tonal variations is guaranteed throughout the run and by memorizing the working conditions reduces drastically color adjustment times as it reproduces the same printed tone in subsequent repetitions.

I-ICS is a centralized control system for flexographic and gravure printers that adapts to any printer and number of printing stations (colors) on the market, and is presented with multiple installation options in terms of cabinets, supports or adaptations to different machines.

It is controlled with a very intuitive software on a touch monitor with which you can manage the current working conditions such as color labels, concentration, temperature, pH, solvent formulas used to maintain viscosity or clean, evolution graphs and a history of works to reuse them whenever desired.

SAME TONE PRINTED THROUGHOUT THE WORK

REDUCES COLOR ADJUSTMENT TIMES IN REPETITIONS

CAN BE UPDATED AFTER THE FIRST INSTALLATION BY ADDING NEW FEATURES ALREADY EXISTING OR FUTURE DEVELOPMENTS

CONFIGURABLE FOR ANY MODEL OF FLEXOGRAPHIC OR GRAVURE PRINTER, CARDBOARD OR IN SPECIAL APPLICATIONS

SERIAL INTEGRATION WITH THE INK DRIVE LINE

INTUITIVE AND VERY EASY TO USE

AVAILABLE OPTIONS FOR AUTOMATIC WASHING, FILLING, CALCULATION OF CONSUMPTION, ALSO CUSTOM DESIGNS

DATA COLLECTION AND TEMPERATURE AND VISCOSITY MEASUREMENTS FOR USE IN UPCOMING WORK

FEATURES OF OUR INK CONTROL SYSTEM

CONCENTRATION CONTROL – VISCOSITY

Considering the viscosity and temperature variables, our color control module keeps constant the concentration that corresponds to the relationship between the pigment + resin and the solvent/water. The system can compensate the viscosity variations caused by temperature changes.

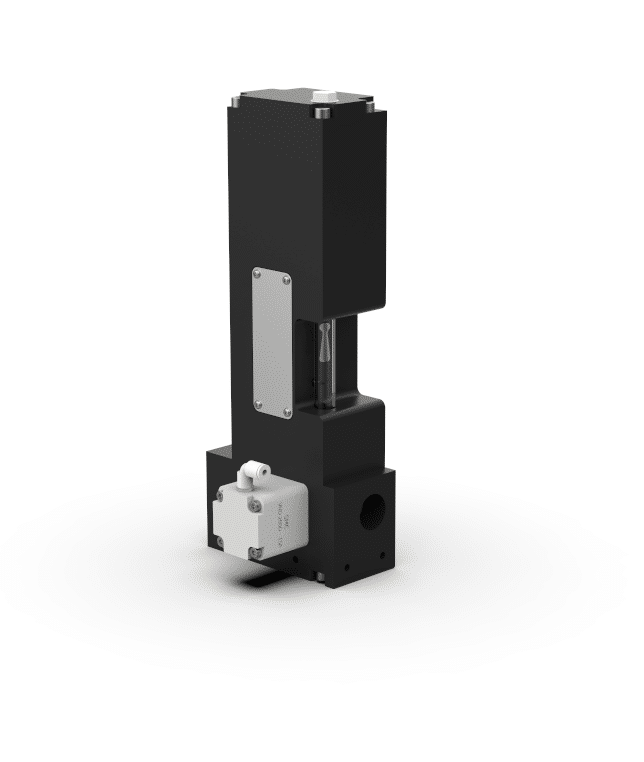

Viscosity is constantly measured by measuring the fall time of a body into a tube through which ink flows. In addition, the measurement unit incorporates a probe to know the temperature at all times.

The viscosity and temperature data are sent to the computer where they are interpreted to calculate the concentration of inks in %.

This system measures even more accurately than other viscometers based on measurement in different theologies ultrasonic, cups, pressure variation etc.

Temperature Control

Its mission is to keep the temperature of the ink stable within appropriate limits with a precision range of +/- 1º C.

The standard system cools the ink, and a heating system can be incorporated.

With a stable ink temperature, we get:

- Best results in the quality of the print by decreasing the point gain in color selections and improving the profiling in spot colors.

- Dryingcontrol, solvent-based ink does not dry on the plate and is transferred to the printed medium with better profiling and intensity. In water-based, the ink is more stable by avoiding variations in the pH by

- It prevents the absorption of water by hydroscopy of the ink obtaining brighter

- Important solvent savings by preventing evaporation and achieving a stable concentration.

Solvent Mixer

It allows to create formulas of up to 4 different solvents to preparer, in line, the dilution solvent for color control and cleaning used individually in each printing station. The formulas are associated with each printing station and saved on the tab for future repetitions.

In this way, inks of different technologies can be used in addition to adapt the formula of the solvent used depending on the ambient temperature and humidity or the speed of printing.

Solvent Consumption

It quantifies the solvent consumed in each printing station, using flow sensors, discriminating whether it is used for washing or viscosity control and offers reports on the amount of solvent used in a certain period of time or in a certain job. Presents the result in graphs and reports.

With this consumption measurement system you can know the production costs of each job and make forecasts of solvent purchases.

pH control for water-based ink

It is a pH control module that far exceeds market standards in its area of action. It is intended for water-powered inks, automatically measures and corrects the PH levels of the ink used while keeping all the qualities of the ink stable.

It consists of sensors, one for each unit of measurement, controlled by a Software and with an additional valve of PH corrector.

pH control in water-based inks allows you to adjust the drying. By decreasing the pH level, fast drying inks are achieved and thanks to the automatic control the risk of defective printing by inks with too low pH levels is eliminated since the tendency of an ink in production is to lose pH level.

Magnetic ink filters

Filters with magnets are incorporated into the ink input line to remove impurities that can damage the system control and printing unit. Magnets remove metal particles that normally come from the blades of the printing body. There are different filter mesh steps, inaddition, the filter body acts as an expansion deposit in pneumatic pump circuits minimizing the water hammer caused by them.

During printing all kinds of solid waste fall into the ink, the filters prevent these particles from passing into the ink circuit avoiding printing defects, scratches on the chromed gravure cylinders or on the flexo anilox, which are deposited in pipes and ink impulsion pumps.

Available with different configurations and thread steps.

Agitators to remove foam and mix the solvent or water with the ink

The agitators are presented as one more module of the I-ICS system and improve the mixture between the ink and thesolvent, reduce the foam that can be generated in the ink container minimizing the adverse effects that this can cause in the print. It is installed on a stainless-steel support and is operated with automatic from the desk of the system.

Also available as an independent pumping, stirring and filtering system.

It can be configured with different arrangements of inputs, outputs and thread steps.

Optional integration and functionalities

The I-ICS ink control system can be integrated with other of our systems in a single control panel. There are automatic washing systems for flexographic and gravure machines, automatic filling systems for tintanks, ink consumption calculation systems or any other special functionality that can be custom developed according to customer specifications.

MULTIPLE COMBINATION POSSIBILITIES

All I-ICS modules: Ink Control, Temperature Control, Agitators, Solvent Consumption Measurement, pH Control, Independent Solvent Mixing and Magnetic Ink Filters, are designed to be added to the printing equipment under the same chassis and on the same control panel.

Both water inks and solvent inks can use:

In the case of solvent inks these two modules can be added:

And for water inks we have an exclusive module:

ADVANTAGES THAT WE OFFER YOU IN INELME FOR THE CONTROL AND CONCENTRATION OF INKS

Traditionally, viscosity has been the variable used by printers to maintain color in flexographic and gravure printing. As a result of our obsession to improve and innovate in each process, at Inelme we questioned whether viscosity was the only factor that influenced color. And we gave the key: temperature. It was then that we developed I-ICS, which adds to the viscosity the control of the temperature of the ink thus calculating the concentration of solids and thus guaranteeing a homogeneous color throughout the entire run.

OTHER SYSTEMS

- Viscosity

- Only temperature control

- Temperature control with plastic pumps with manual control

- Degradable plastic measuring unit

- Measurement by sphere drop time

- Parallel installation

- Dialog terminal without memory

INELME SYSTEM

- Measurement of ink concentration (viscosity and temperature)

- Multitude of expandable modules, versatility

- Temperature control with electronic control pneumatic pumps

- Unit of measure of high durability and chemical resistance

- Measurement by dart fall time

- Serial or parallel installation

- PLC + PC with job storage software

DO YOU WANT MORE INFORMATION ABOUT THE INK CONCENTRATION CONTROL SYSTEM?