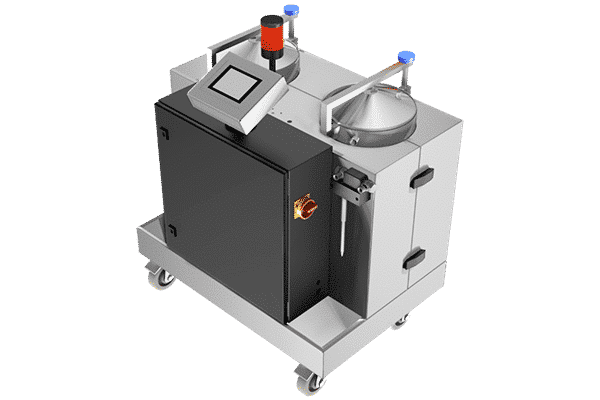

Solvent-free adhesive mixer for lamination

The I-AMX is two-component adhesive mixing equipment available in three versions, without own tanks and with tanks of 30 or 60 litres for glue and catalyst.

BICOMPONENT ADHESIVE MIXER

The system mixes in the desired proportion of adhesive and catalyst taking the necessary amount of each of the components from their corresponding tanks with the thermal heating system of 30 or 60 litres (depending on model) by volumetric gear pumps driven by gear motors and controlled by frequency inverters.

Each of the two pumps drives a component, through the flowmeters and a heated hose, to a mixing nozzle located at the application point.

The system is prepared to manage two signals from the laminator, a sensor that tells us when it is necessary to perform a dosage (when the mixing level drops), and meter count – signal through by which the equipment can report the amount of adhesive dosed per cm2 of the laminated product.

ADVANTAGES OVER OTHER SIMILAR EQUIPMENT

DO YOU WANT MORE INFORMATION ABOUT THE AUTOMATIC MIXER I – AMX?