LASER ANILOX ROLLS CLEANING SYSTEM

Up to 80% time savings in Anilox Cylinder Cleaning with I-Lac machines

Cleaning anilox cylinders has always been one of flexo printers’ biggest concerns. If the cylinders are not perfectly clean, they reduce their transfer capacity and therefore color intensity is lost in the printing, with the consequences for production that this can have: invalid prints, longer start-up times, etc.

I-LAC solves this problem effectively thanks to the laser that deeply removes the dried ink from the interior of the cells without damaging the cylinder cells. A specially designed optical laser vaporizes any residue and cleans the remains of dried ink, adhesives, waxes, silicones, etc. Laser technology allows cleaning without exerting any mechanical or thermal action on the anilox cylinder, which allows us to clean even after each use and preserve the useful life of the anilox rollers for much longer.

Accurate and reliable laser technology

The new laser anilox cleaning system uses fiber laser technology to emit a beam through a series of diodes mounted on an optical fiber. The anilox cells are completely clean, achieving a nominal contribution of 100%, being able to clean any type of color, ink base or adhesive.

During the printing processes, the ink used is deposited at the bottom of the alveolus of the anilox cylinders and the volume of the cylinders is reduced and consequently, the contribution of the cylinder is reduced.

Using laser technology, the laser anilox cleaning system removes the ink from inside the cylinder cells, extracting any type of ink, glue or varnish. In this way, 100% of the initial volume of the cylinder is recovered, being able to keep the color intensity always constant.

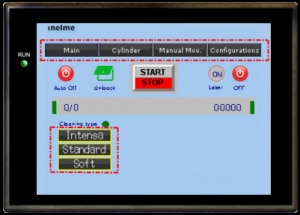

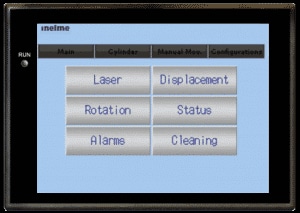

Intuitive software

The laser anilox cleaning system is controlled by a user interface that allows easy and intuitive operation of the machine without the need for additional knowledge.

Easy setup

Using the touch screen you can adjust the parameters of the anilox as well as view the cleaning status at all times.

Accurate and reliable laser technology

I-LAC machines are available from a maximum length of 500 mm to 3500 mm (cylinder without shafts), covering any need, from the label sector to the case of special needs or large formats.

I-LAC F50-15

I-LAC F50-20

Maximum cleaning length (cylinder without shafts): 1500 mm

Minimum cylinder diameter: Ø50 mm

Maximum cylinder diameter: Ø350 mm

Maximum cleaning length (cylinder without shafts): 2000 mm

Minimum cylinder diameter: Ø50 mm

Maximum cylinder diameter: Ø350 mm

DO YOU WANT MORE INFORMATION ABOUT THE LASER ANILOX ROLLS CLEANING SYSTEM?