I-LAC

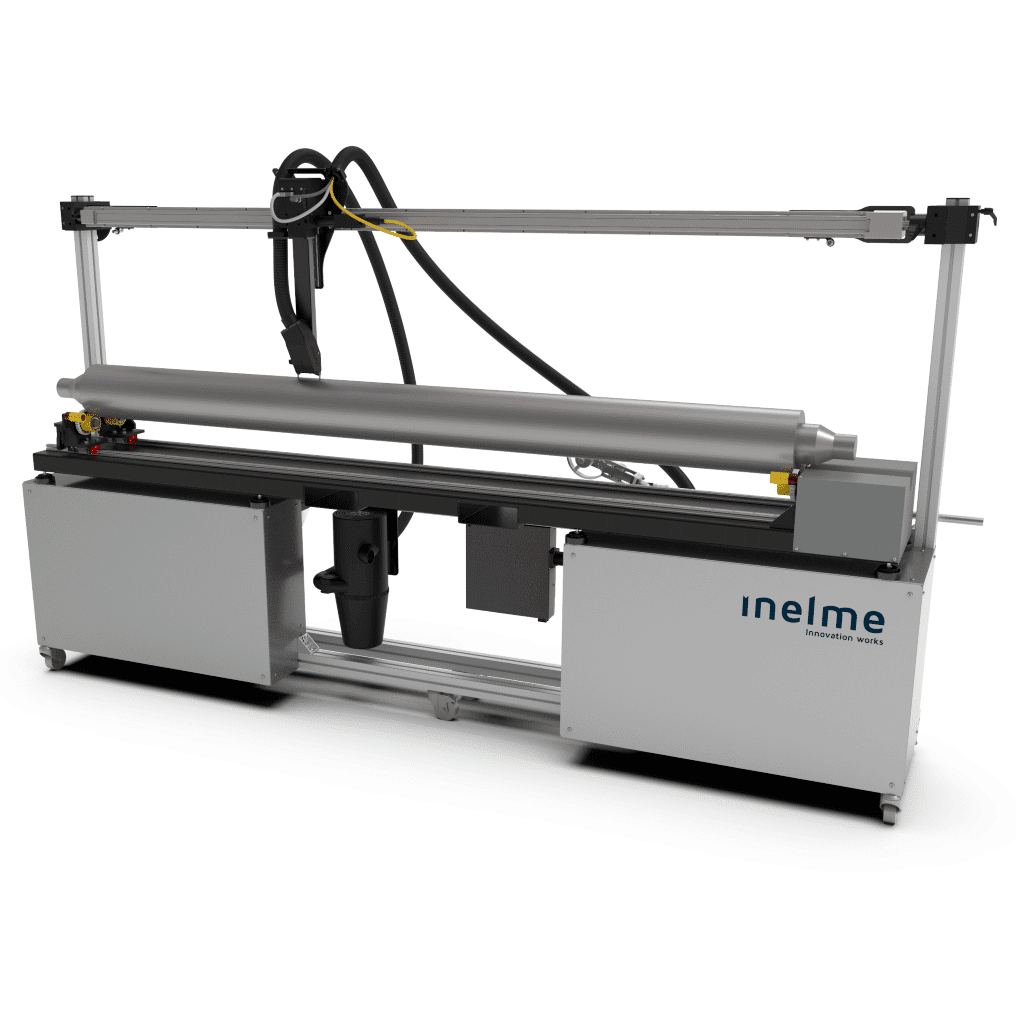

PORTABLE ANILOX WASHING MACHINE

The anilox laser cleaning system removes ink from

the inside of the cylinder alveoli

I-LAC

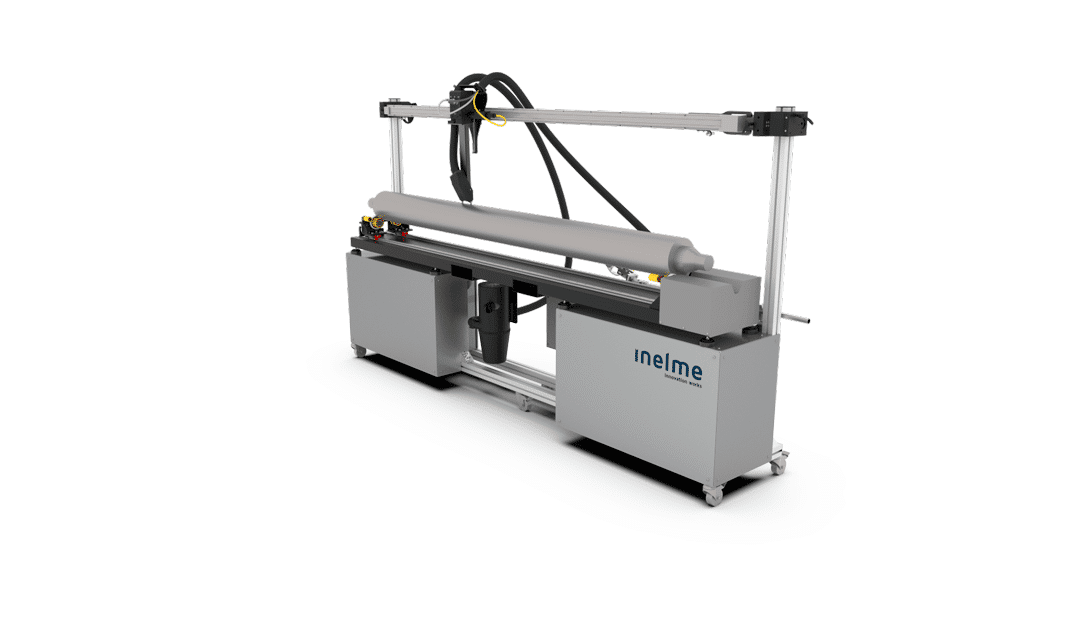

Portable anilox washing machine

During the printing processes, the ink used is deposited at the bottom of the alveoli of the anilox cylinders and reduces the volume of the anilox cylinders and, consequently, the contribution of the cylinder is reduced.

Using laser technology, the anilox laser cleaning system removes ink from the inside of the cylinder alveoli, removing any type of ink, glue or varnish. In this way, the initial 100% volume of the cylinder is recovered, being able to maintain the intensity of the colour always constant.

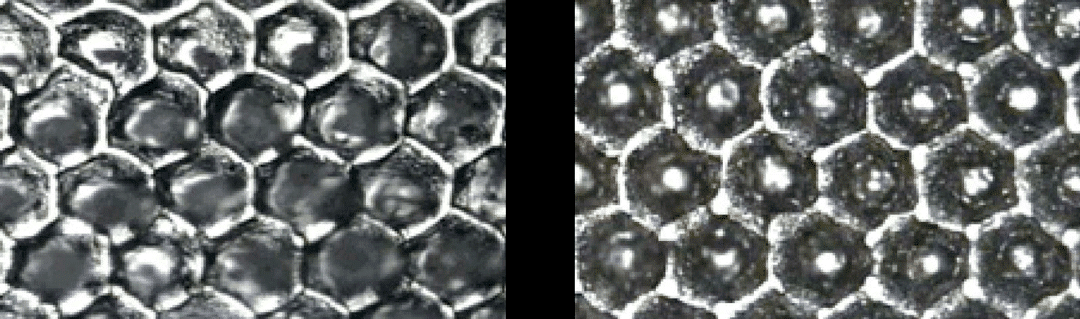

Dirty and clean alveoli

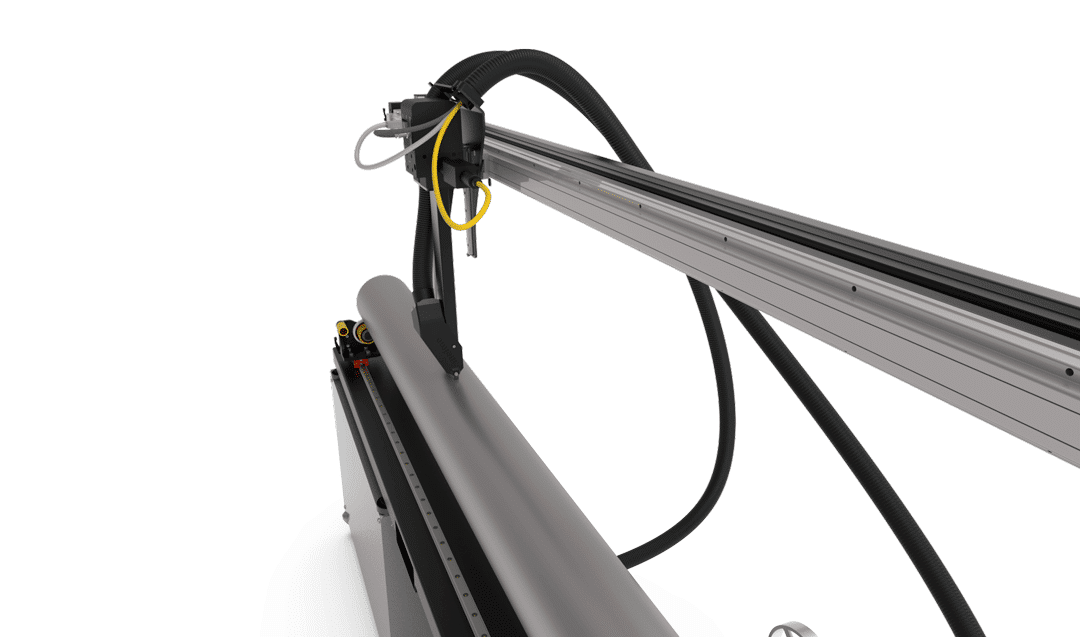

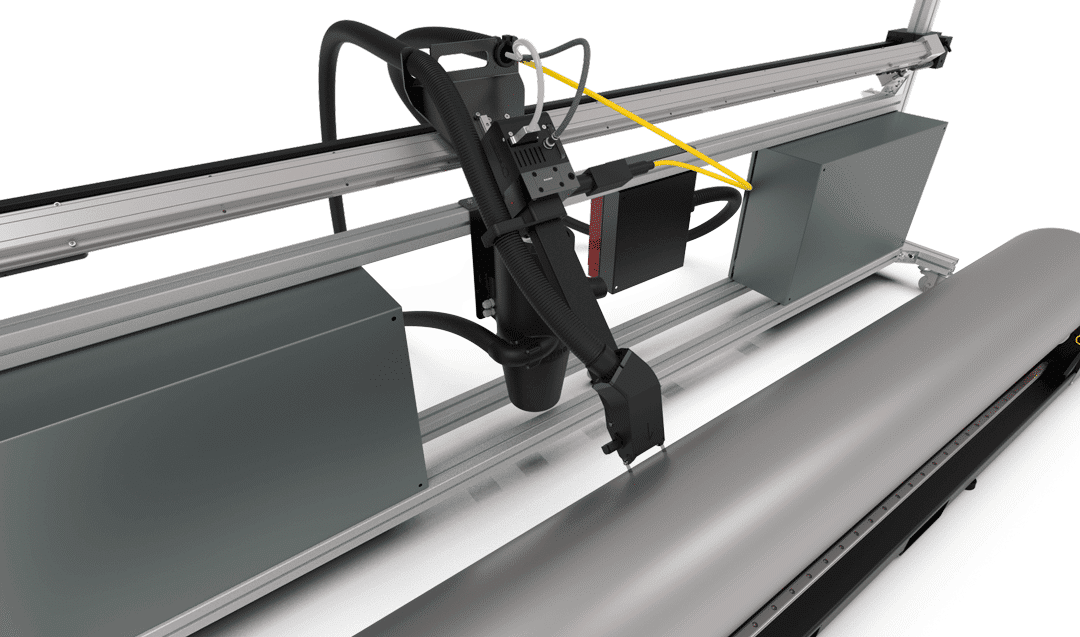

The cylinder to be cleaned in models with rotation system, is placed on supports that make it rotate while the laser head advances horizontally along the entire surface of the cylinder.

All this process is controlled by servo drivers and frequency inverters so that the accuracy in the displacement is assured. The operator simply places the cylinder in the equipment and activates the cleaning from a simple and intuitive software installed on a touch screen.

Machine elements

Electronics

The machine is controlled with a PLC and a touch screen, OMRON brand. The operator can easily enter the parameters and external measurements of the anilox and start the washing process.

Operator interface

The touch screen, in addition to the anilox configuration, also allows you to view the status of the machine at all times, time to end the cleaning cycle, list of current alarms or historical alarms, etc. The machine also has illuminated pushbuttons and an emergency stop for the easy, fast and correct operation of the unit.

Laser

The machine has a new laser with diode technology that reduces maintenance to a single intervention every 100,000 hours (on average) of operation.

Extraction System

The machine uses an extraction system that allows the capture of all particles in a reusable filter.

Rotation motor

The rotation motor allows the rotation of the anilox (Y movement) by means of a reducer, frequency inverter and rubber-coated rollers so as not to damage the surface of the anilox.

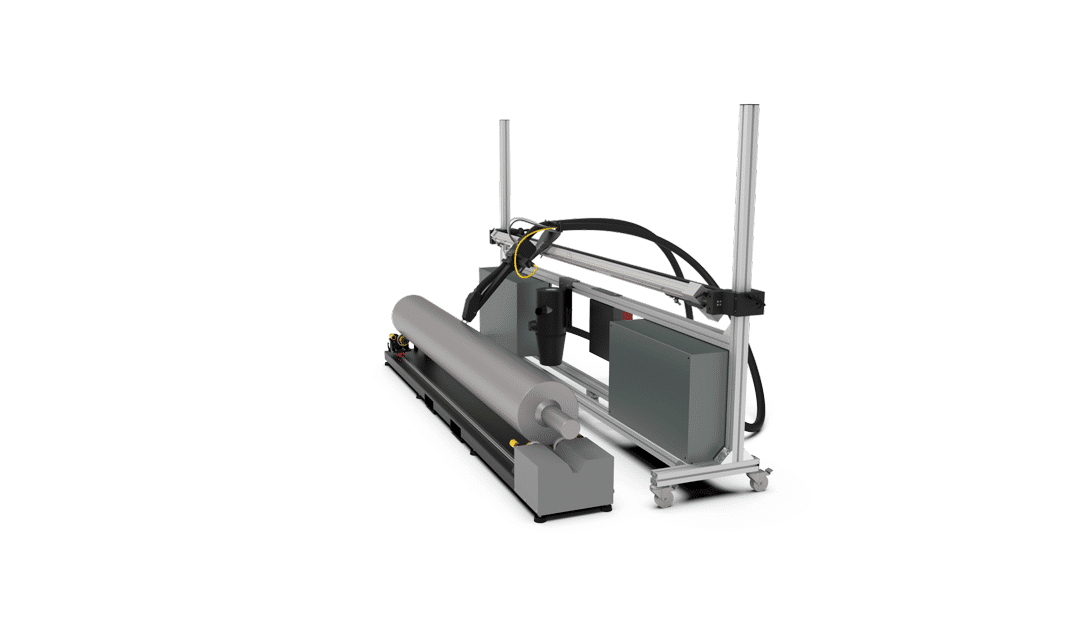

Portable

With this model it is possible to clean the rollers inside the printer. The chassis with electronics independent of the laser head-scroll bar assembly allowing the latter to be inserted inside the printing unit for cleaning.

The rotating motor of the printing body is used for the cleaning process, placing a rubber wheel is used to coordinate the rotation of the cylinder with the displacement of the head at all times.

Advantages over other cleaning alternatives

Possibility of cleaning the cylinders without removing them from the printer reducing maintenance times and the risks of damaging the cylinder.

The alveoli are completely clean after the process.

There is no wear on the cylinder surface. For many cleanings that are carried out, after each of them the contribution will be the original of the cylinder.

No waste is generated, no chemical or consumable component is needed that must be projected against the cylinder.

Cleaning speed, in 30 minutes a cylinder of 1000 mm in length and Ø 150 mm is completely clean. Easy handling.

No technical knowledge is necessary to operate the equipment, the cylinder is introduced, its length and diameter is reported, and cleaning begins.

Specifications

Supply voltage ………………………………………..220-230V 50Hz/60Hz

Maximum installation power.…………………..5Kw

Average consumption ………………………………3Kw

Cleaning speed

The cleaning speed for the 60W laser is about 25min/m2. Approximate cleaning time for 1200mm table cylinder 150mmØ = 0.56m2/area = 14-16 minutes*.

*NOTE: Estimated times may vary depending on the characteristics of the cylinder (linearity, input and saturation of the alveoli) and the configuration of the I-LAC equipment.

Material included

The washing unit includes all the elements and materials necessary for the commissioning and proper operation of the machine. The customer should only prepare the area where the machine and the power supply are to be installed.

DO YOU WANT MORE INFORMATION ABOUT THE PORTABLE ANILOX WASHING MACHINE?

When you submit a form, you will be asked for information such as your email and name that are stored in a cookie so that you do not have to re-fill them in future shipments. By submitting a form you must accept our privacy policy.

- Responsible for the data: Sistemas Inelme S.L.

- Purpose: Respond to form requests.

- Legitimization: Your express consent.

- Recipient: Sistemas Inelme S.L. (data stored only in email client)

- Rights: You have the right to access, rectification, deletion, limitation, portability and forgetting your data.