Lamination solvent adhesive Mixer

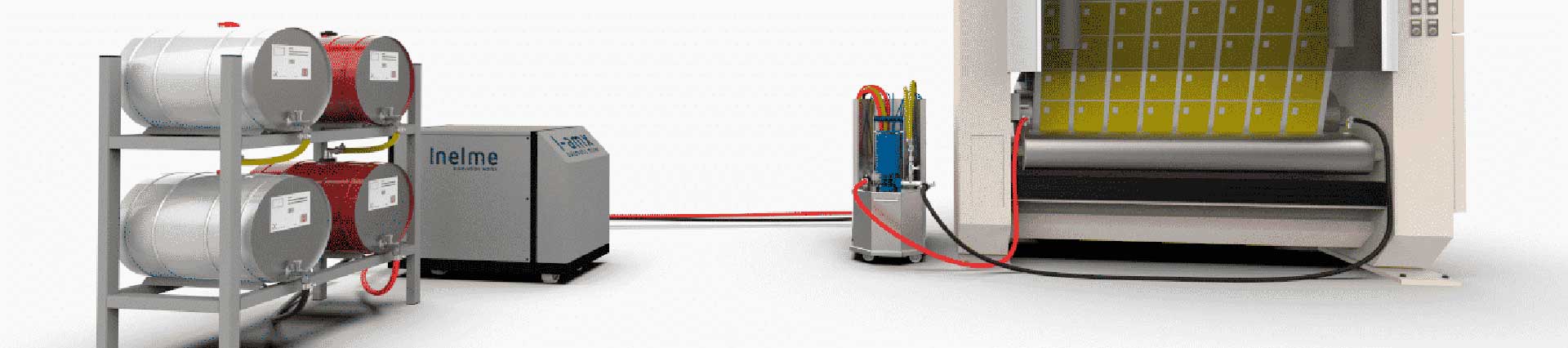

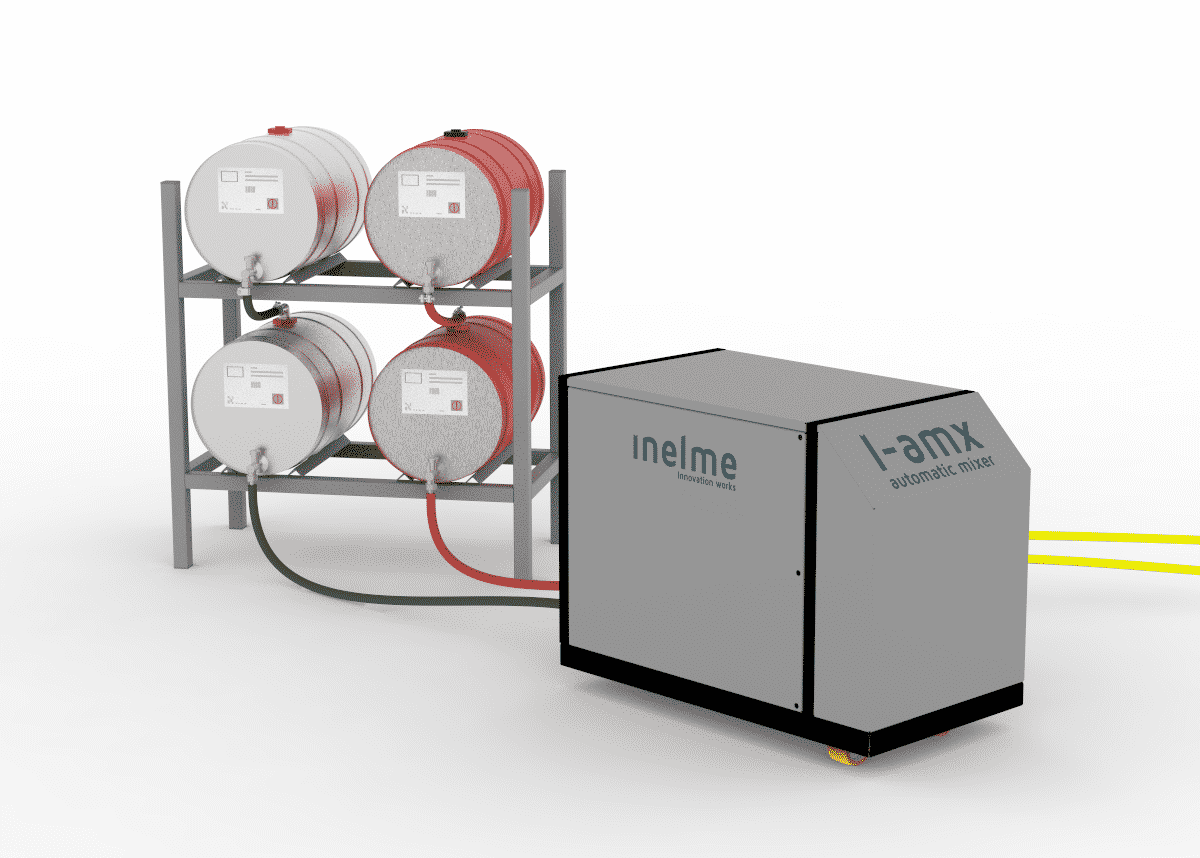

The I-AMX MC-V is a solvent-based two-component adhesive mixing equipment with a pump-to-laminator system, automatic filling of the intermediate tank and viscosity control.

AUTOMATIC MIXER WITH VISCOSITY CONTROL

The installed viscometer that is responsible for maintaining the proportion of solvent in the mixture has an automatic washing system designed for catalytic glue control equipment that performs solvent rinsing routines that prevent the deposition of catalyzed adhesive during use. It is the same solvent used for washing that was later used to add it to the mixture that is being prepared as it is consumed.

In the viscometer the tail, driven by the pump, circulates through the measurement unit where, as a function of the time of fall of a metallic body between two inductive detectors, the viscosity is calculated. The software decides if dilution is necessary using the solvent in the tank. The rinse cycles are carried out at the time of dilution, once the unit of measure is full of solvent after dilution, a valve is opened that returns the solvent to the tank by recirculating until the software estimates that the unit has been cleaned correctly. . After cleaning, normal work continues and the solvent accumulated in the unit begins to dilute the glue. From time to time the system flushes the unit of measure if it was not necessary to dilute the glue in that time.

ADVANTAGES REGARDING OTHER SIMILAR EQUIPMENT

- Select the viscosity of the desired glue in ford 4 cup format.

- Automatically update required selection with actual glue viscosity to facilitate system startup.

- Choose operation in manual or automatic mode. In manual mode the equipment only takes measurements and the addition of solvent is the responsibility of the operator. In automatic mode the system is in charge of controlling and maintaining the selected viscosity.

- Program concentration warning alarms outside the established limit or error messages in the operation of the measurement units.

- Display on the screen all the operating parameters of the equipment (start, stop, automatic, error).

- Carry out auto-wash cycles, at predefined time intervals, thus improving the precision of measurements when working with double-component glues.

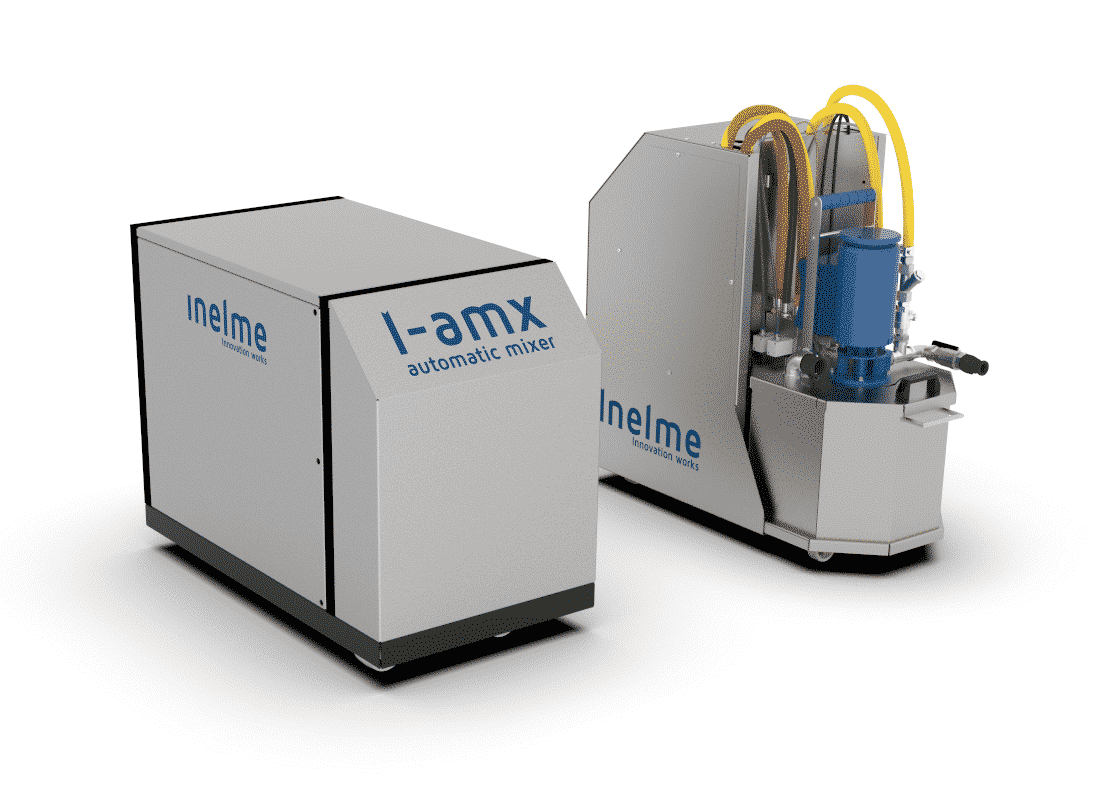

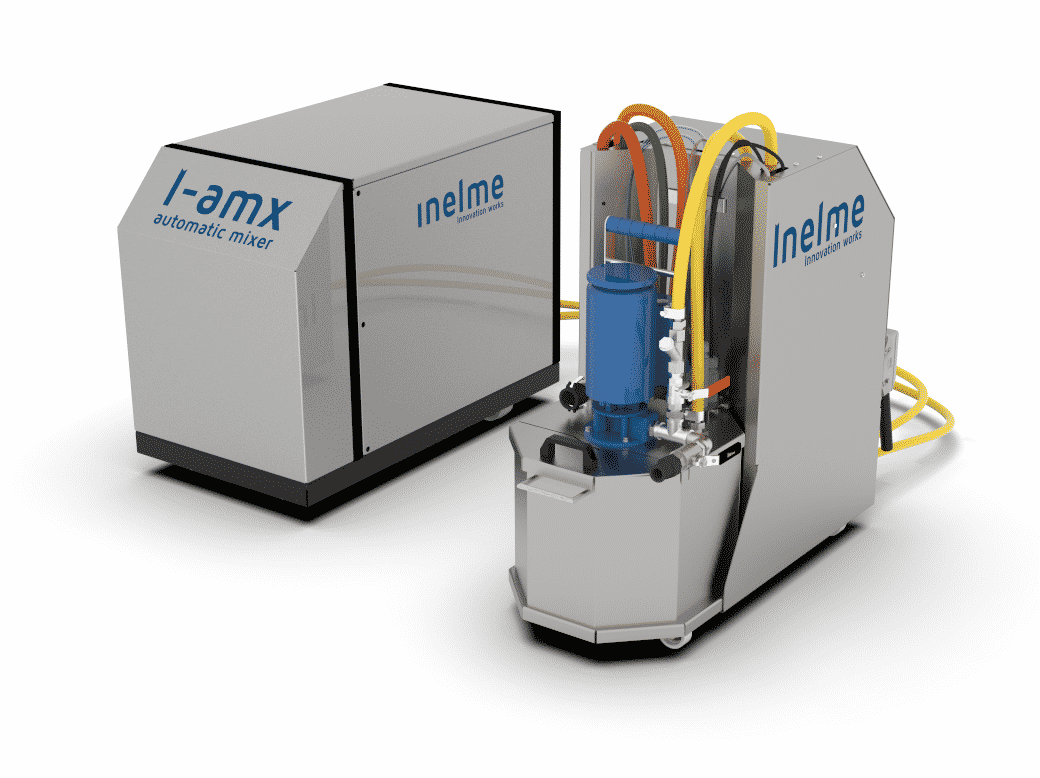

Main chassis

It contains the dosing pumps and flowmeters as well as the motors that intervene in the dosing process. It is equipped with a holder for the dosing nozzle after finishing the job.

Mixed glue tank (with viscosity control)

Double tank, an intermediate tank for storing the already mixed product and a second contiguous tank for the solvent to be used in the concentration control and the cleaning process. These tanks are equipped with level sensors and solvent supply (pneumatic) and product (electrical, ATEX) pumps.

In it, the viscosity control is carried out by adding solvent in the event that the viscosity is above the selected one.

DO YOU WANT MORE INFORMATION ABOUT THE LAMINATION ADHESIVES MIXER?