AUTOMATIC CLEANING SYSTEM

Leading washing system for Flexo and shaft, discover our I-ACS system in its 1 pump versions and double pump

Solutions for the professional of flexography and rotogravure

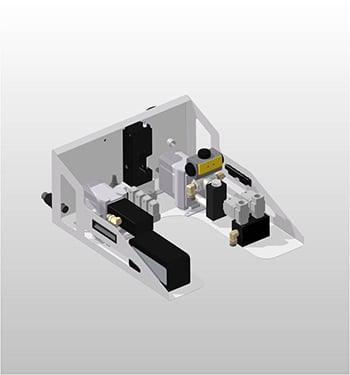

The I-ACS Automatic Cleaning System supplies ink to the Doctor Blade Chamber through an adjustable flow and ensures at all times the necessary volume of ink in the chamber for a correct supply. Once the work is finished, the system allows to clean the entire ink circuit and can clean all the printing bodies simultaneously.

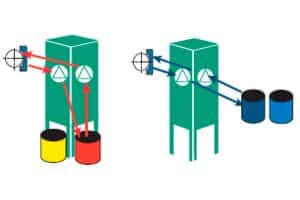

We have two versions of the I-ACS system, a basic system with a single impulse pump and return from the chamber by gravity and the complete system with double pump that ensures the pressure inside the doctor blade chamber and optimizes solvent / water consumption as well as minimizes cleaning times.

ALL THE ADVANTAGES OF THE LEADING SYSTEM OF CLEANING FOR FLEXOGRAPHY AND ROTOGRAVURE

OUR TWO MODELS OF AUTOMATIC CLEANING MACHINES

I-ACS Complet

I-ACS Basic

NOT INCLUDED:

COMPARATIVE SHEET BETWEEN MODELS

* Times and consumption taken in laboratory tests with an 8-color system and a central drum printer, changing black to white. These numbers may vary depending on the equipment, types of inks, distance from the equipment to the printer, environmental conditions, etc.

HOW THE AUTOMATIC CLEANING SYSTEM WORKS

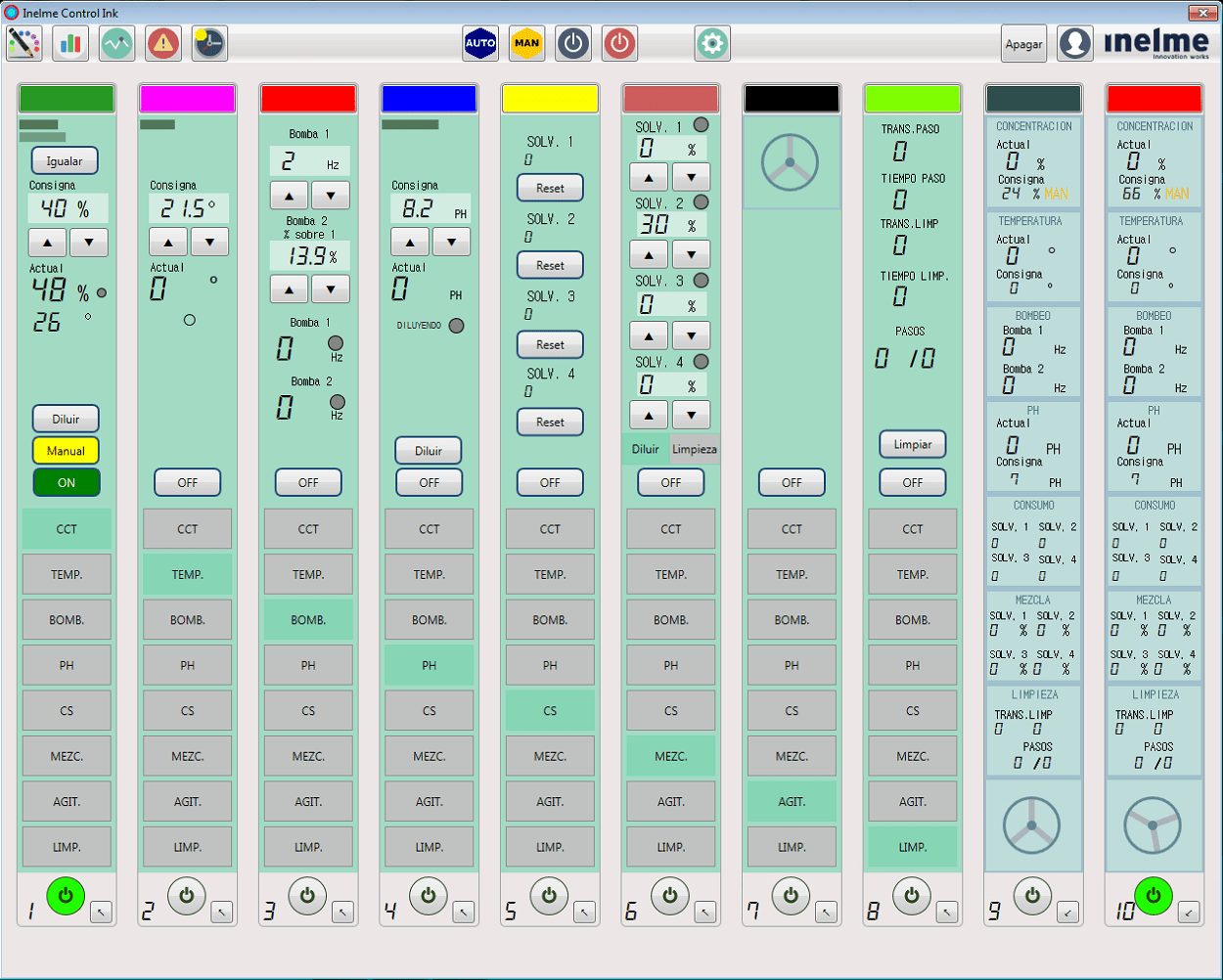

In the pumping process, the equipment employs a pneumatic pump to absorb in from the standard cube and drive to the doctor blade chamber. A second pump* absorbs from the doctor blade chamber. The working frequency ratio of these two pumps and consequently the flow of impulsion and absorption are configurable separately so as to avoid any problem of over-pressure in the chamber that could generate overflows.

The system allows to configure different cleaning processes depending on the needs, quick cleanings to use similar colours or deep cleaning for changes from black to white without any contamination. In any case, the common cleaning process begins with emptying the ink circuit and the doctor blade chamber for practically total reuse (see technical characteristics) of the ink in future work. Subsequently and through an external pump, it is introduced into the solvent or water circuit (depending on the type of ink) that has already been used in previous cleanings to remove the remains of ink that could remain in the circuit. This solvent / water is again removed from the system by another external pump and stored in a tank for future reuse use. In a second cycle, the system performs the same procedure but this time using clean solvent / water as a rinse to ensure complete cleaning of the circuit and the doctor blade chamber. Through this procedure and the combined use of reused solvent / water and clean solvent / water, it is possible to minimize consumption in each cleaning without sacrificing perfect results.

*Depending on model

INKING PHASE

2 electronic control pneumatic pumps:

EMPTYING PHASE

Electronic redirection pumps:

WASHING CYCLE

I-ACS Complet directs recycled water / solvent from the tank or line by passing it through the entire circuit by using both pumps, all colours at the same time:

SET OF DEPOSITS

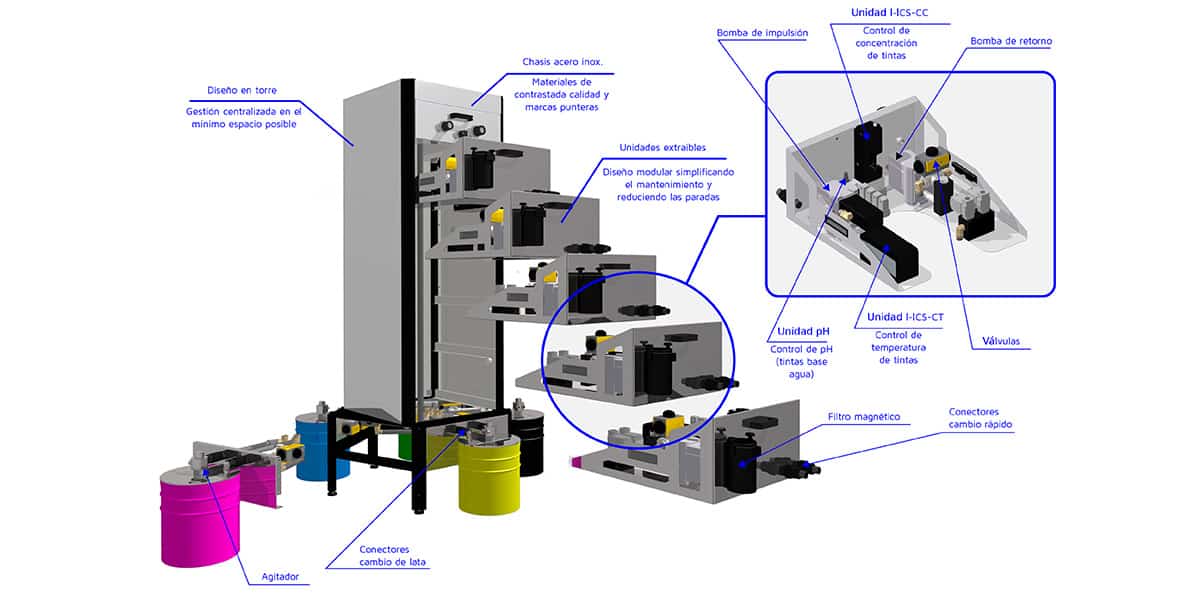

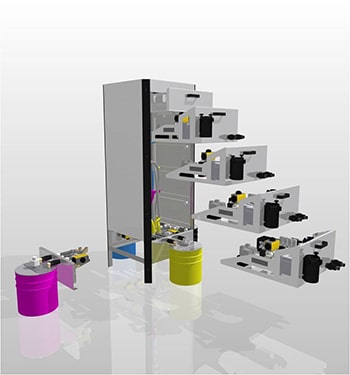

VERTICAL DESIGN

MODULAR DESIGN

REMOVABLE TRAY

Each tray integrates*

*Depends on version

EASY ACCESS

SOFTWARE AND MONITOR

MAXIMUM SECURITY – ATEX REGULATIONS

The system is approved under ATEX regulations to work in potentially explosive environments with Exia protection. The pumps used are ATEX stainless steel. The design of the equipment is specially designed for the total ergonomics of the user and to minimize work accidents.

DO YOU WANT MORE INFORMATION ABOUT THE AUTOMATIC CLEANING SYSTEM?